WHAT WE DO

ELECTRICAL AND TECHNOLOGY SERVICES.

Our specialized electrical, technology, and maintenance teams deliver uncompromising quality and ensure projects are completed safely, on time, and on budget. Our dedication to innovation, integrity, and accountability keeps our standards high, and we stand by our work long after the job is done.

Electrical

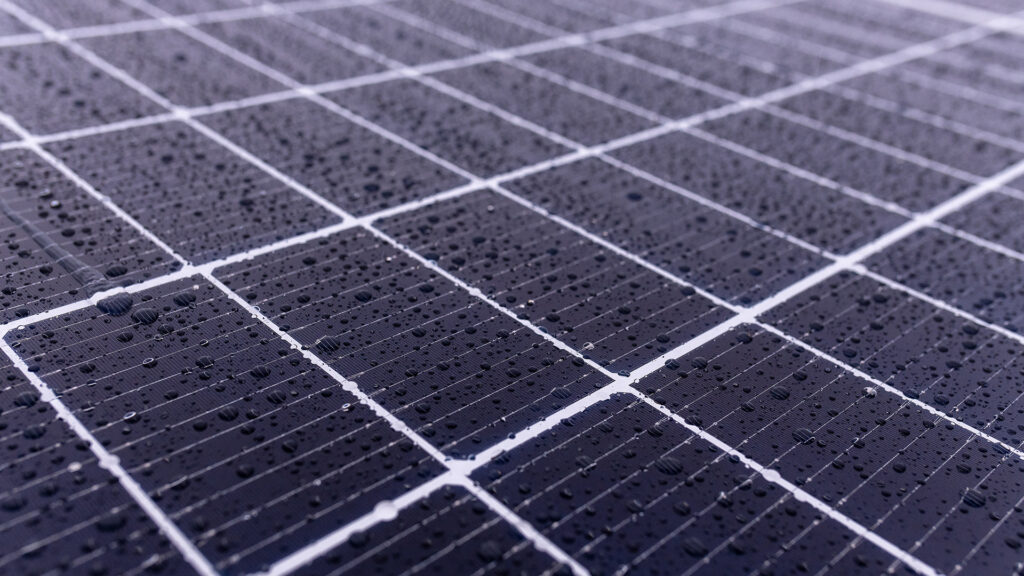

From electrical distribution and lighting to fire alarm and EV charging, we deliver custom electrical solutions for all project types. Our innovative thinking and award-winning project management capabilities enable us to tackle any challenge or scope requirement to bring your vision to life.

Technology

Our in-house Technology specialists provide unmatched systems integrations for full lifecycle systems management of security, structured cabling, building controls, and healthcare technology solutions. This includes estimation, design, installation, and upgrades to keep your facility future-ready.

Electrical engineer using measuring equipment to checking electric current voltage at circuit breaker and cable wiring system for maintenance in main power distribution board. Maintenance

Whether it’s a new or old build, we work to breathe life into your facility through quality maintenance solutions. From preventative maintenance and insurance requirements to electrical and technology systems upgrades, we work to help you avoid costly shutdowns and keep your facility operating smoothly.

creating value for people in everything we DO

All

Electrical Maintenance Residential Technology

All

Commercial Industrial Infrastructure Institutional Residential Strata

All

Agriculture Civil Infrastructure Educational Entertainment Financial Government Government-Federal Government-Municipal Healthcare High-Rise Hospitality & Tourism Law & Law Enforcement Manufacturing Military Mining Oil & Gas Ports/Terminals Ports & Terminals Pulp & Paper Religious Residential Retail & Shopping Smelters Sports & Recreation Tenant Improvement Tourism Transportation Utilities

Clear Filters