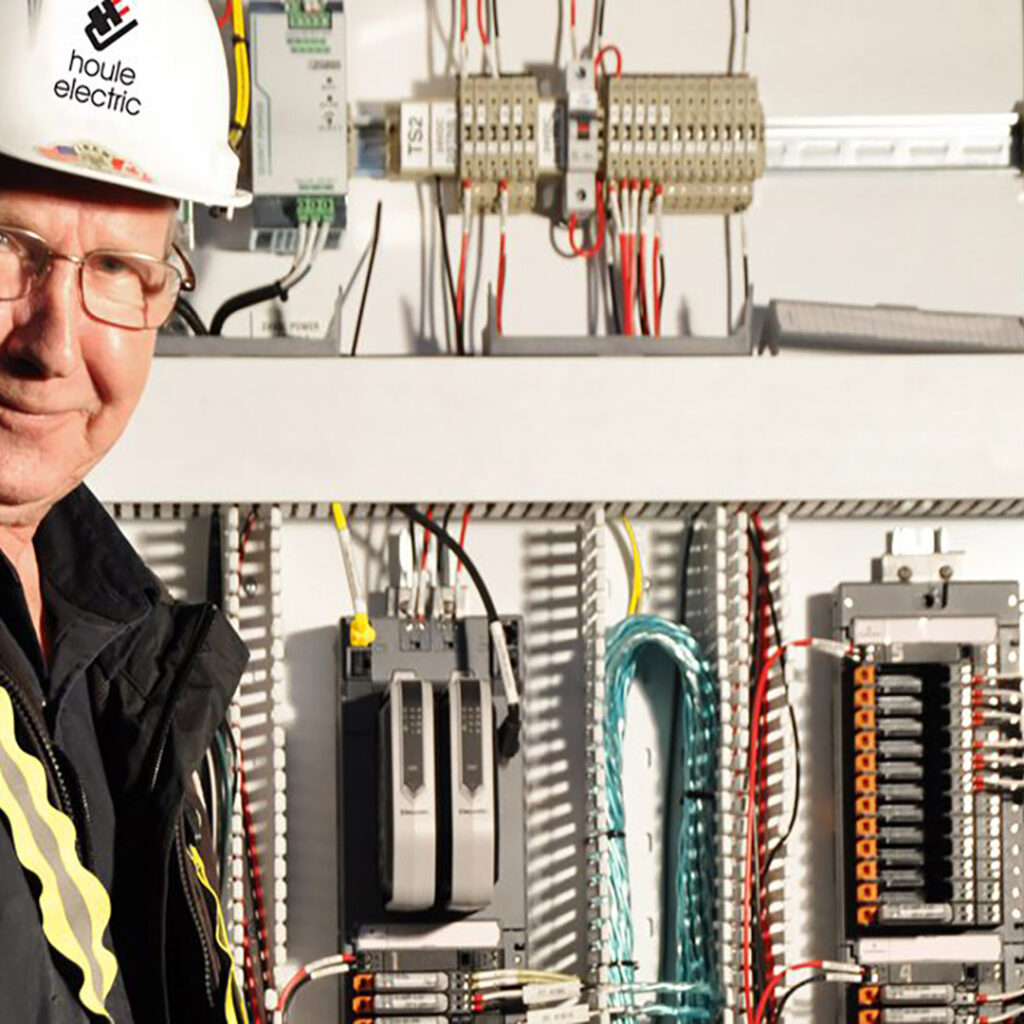

Mount Milligan—Electrical & Instrumentation project

- 468,000 Feet of Large Cable

- 865 Instruments / Control Devices

- 242 Marshalling/ Control Panels

Projects / Industrial

Project info

Mount Milligan is a copper-gold mine located 155 kilometres northwest of Prince George. This expansive project consisted of building the mine and the refining building from the ground up, taking two years to complete from start to finish.

Our scope for this project included all electrical instrumentation, security and structured cabling solutions, including over 259,000 metres of Teck cable. We worked on several large ball mills, a one-kilometre conveyor, and several smaller conveyors.

One logistical challenge on this project was the transportation of over 320 electricians and various materials to a location three hours outside of Prince George with only logging road access. This took significant coordination from our project team to ensure that everything and everyone got to and from site at the right time.

We also faced extreme winter conditions, with snow covering the ground six months of the year, significant planning was required to ensure we met the project schedule. This project achieved more than five million hours recorded by all trades without any lost-time injuries, earning all on-site trades the John Ash Safety Award.

Details

- Sector: Industrial & Infrastructure

- Completion: 2013

- Owner: Thompson Creek Metals Company

- Award: John Ash Safety Award